Gold Plating on Connectors - Benefits, Applications, and Alternatives

Gold plating has long been a standard in the connector industry, offering a unique combination of durability, corrosion resistance, and electrical conductivity. Its application is crucial in aerospace, military, and telecommunications, where reliable performance under harsh conditions is paramount. This blog explores the key benefits of gold plating on connectors, the diverse applications it serves, and some alternative materials. Understanding these factors will help you make informed decisions about which connectors are best suited for your needs. Some factors we'll discuss today are:

- How is Gold Plating Beneficial?

- Applications of Gold-Plated Connectors

- Passivated Stainless Steel and Other Alternatives

- The Effects of Gold Thickness, Hardness, and Quality

How is Gold Plating Beneficial?

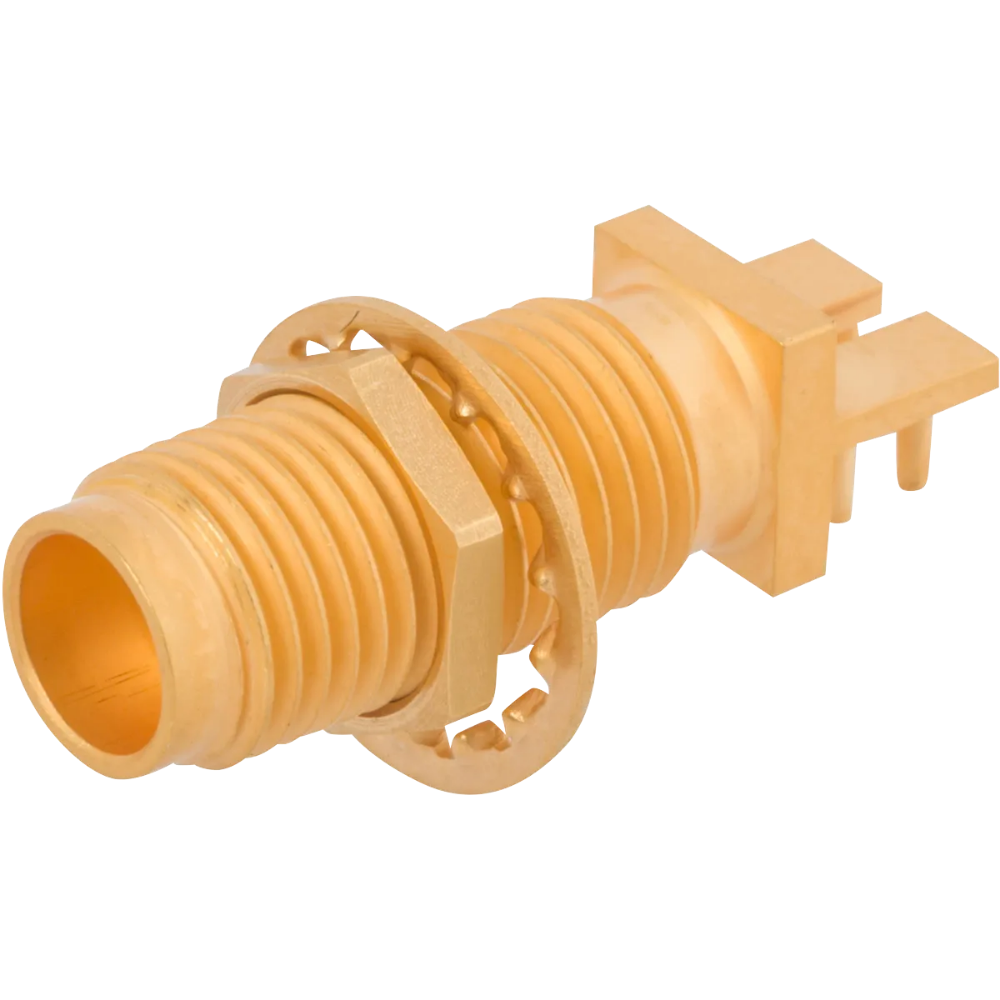

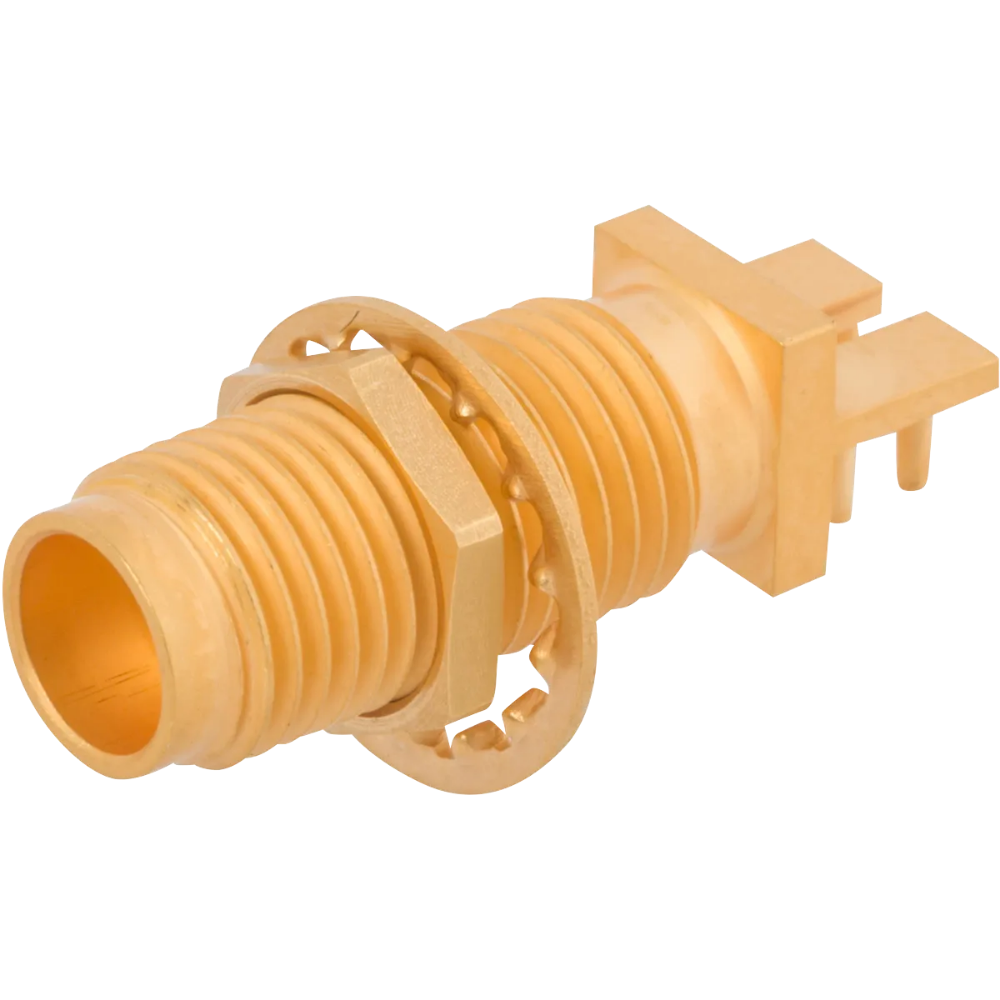

The gold plating on connectors provides durability and corrosion resistance, ensuring consistent performance over time. Its ability to withstand corrosion significantly reduces maintenance needs and extends a connector's lifespan, especially in harsh environments.

|  |  |

Corrosion Resistance

Gold is one of the least reactive metals. It does not react with oxygen or moisture, making it highly resistant to oxidation under environmental stressors. This ensures that it won’t corrode in extreme environments.

Corrosion in connectors typically manifests as rust, base metal bleed-through, or tarnish, reducing electrical reliability. Rust, in particular, reduces reliability by forming an oxide layer that causes connection and conductivity issues. While tarnishing might not always affect performance, it can have cosmetic implications. A tarnished connector may be perceived as unreliable or damaged, leading to concerns about its performance.

Electrical Conductivity

Gold is the third most electrically conductive element, following copper and silver, due to its electron configuration. Although copper and silver surpass gold in conductivity, gold plating on connectors is often preferred because of its durability and corrosion-resistant properties, making it more suitable for long-term use.

Applications of Gold-Plated Connectors

Gold-plated connectors are vital in high-stress environments, such as military and aerospace applications. These areas demand connectors that endure extreme conditions while maintaining superior electrical and mechanical performance.

In addition, gold-plated connectors are valuable in applications that require frequent mating cycles, such as testing and instrumentation. Gold's durability and longevity are ideal for connectors subjected to repeated use.

At SV Microwave, gold plating is applied to various RF connectors, including blind-mate connectors and those with center contacts. Any connector featuring a socket is also gold-plated, as its base, typically heat-treated Beryllium Copper, is prone to corrosion if unprotected.

Passivated Stainless Steel and Other Alternatives

While gold plating on connectors offers numerous advantages, several alternatives exist, including nickel, silver, and passivated stainless steel. These materials can offer cost-effective solutions while providing varying degrees of corrosion resistance.

|  |  |

Passivated Stainless Steel

Passivated stainless steel is commonly used for SV’s threaded connectors and offers an excellent alternative to gold plating. The passivation process involves treating steel with nitric or citric acid to remove free iron from the surface. This treatment eliminates impurities that cause rust and forms a protective oxide layer, making the stainless steel more corrosion-resistant. This process applies to our threaded connectors because of their stainless steel bodies.

Silver

Silver is more conductive than gold and can serve as an alternative in some applications. However, gold’s superior corrosion resistance often makes it the preferred choice.

Nickel

Nickel plating offers a more cost-effective solution than gold. While it provides a degree of corrosion resistance, it does not match gold’s long-term conductivity.

One way SV Microwave utilizes nickel is with nickel underplating beneath the gold plating. This prevents copper bleed-through, a process where the copper base material seeps through the gold layer, leading to corrosion over time.

Gold Plating: The Superior Choice for Critical Applications

While these alternatives provide certain advantages, none can match the reliability, durability, and corrosion resistance of gold plating on connectors, making it the best option for critical applications.

The Effects of Gold Thickness, Hardness, and Quality

The thickness and hardness of the gold layer on connectors can affect performance and durability. SV Microwave uses different gold thicknesses and hardness levels depending on the specific connector's needs.

Thick Plating

Thick gold plating, typically measured at 1.27 microns or above, provides superior corrosion resistance and is favored in applications that face environmental stressors or high mating cycles.

Thin Plating

Thin gold plating, around 0.25-0.76 microns, is sufficient for connectors used in low-stress environments. While it offers a cost-effective solution, thin plating can be porous, which may increase the chances of corrosion. As mentioned earlier, SV combats this with nickel underplating, adding an extra layer of protection.

Gold Hardness

Gold hardness, which varies based on purity levels, affects how well the gold performs under different conditions. With purity levels typically ranging from 99% to 99.9%, hard gold, gold containing more impurities, is particularly suited for connectors that must withstand sliding contact or high mating cycles, as its toughness helps prevent degradation over time.

Gold Embrittlement

Gold plating on connectors in any situation may cause gold embrittlement during the solder cycle, compromising performance. SV Microwave offers a line of Pre-Tinned Connectors designed to remove gold from solderable areas, preventing embrittlement. SV also provides degolding services for cable ferrules, tailored to specific applications. Reach out to our engineers today to learn how this can benefit your design: applications@svmicro.com.

Gold Plating, the Preferred Choice

Gold plating remains the preferred choice for connectors requiring superior durability, corrosion resistance, and consistent performance, especially in demanding environments. While alternatives, like passivated stainless steel, silver, and nickel, offer certain advantages, none provide the same level of long-term reliability that gold does. Whether designing for high-stress applications or seeking a cost-effective solution, understanding the role of plating materials is critical. At SV Microwave, we offer a range of gold-plated connectors and alternative solutions tailored to meet diverse industry requirements. Contact us today to find the best solution for your application at applications@svmicro.com.

recent releases

Gold Plating on Connectors - Benefits, Applications, and Alternatives

Gold plating has long been a standard in the connector industry, offering a unique combination of durability, corrosion resistance, and electrical conductivity. Its application is crucial in aerospace, military, and telecommunications, where reliable performance under harsh conditions is paramount. This blog explores the key benefits of gold plating on connectors, the diverse applications it serves, and some alternative materials. Understanding these factors will help you make informed decisions about which connectors are best suited for your needs. Some factors we'll discuss today are:

- How is Gold Plating Beneficial?

- Applications of Gold-Plated Connectors

- Passivated Stainless Steel and Other Alternatives

- The Effects of Gold Thickness, Hardness, and Quality

How is Gold Plating Beneficial?

The gold plating on connectors provides durability and corrosion resistance, ensuring consistent performance over time. Its ability to withstand corrosion significantly reduces maintenance needs and extends a connector's lifespan, especially in harsh environments.

|  |  |

Corrosion Resistance

Gold is one of the least reactive metals. It does not react with oxygen or moisture, making it highly resistant to oxidation under environmental stressors. This ensures that it won’t corrode in extreme environments.

Corrosion in connectors typically manifests as rust, base metal bleed-through, or tarnish, reducing electrical reliability. Rust, in particular, reduces reliability by forming an oxide layer that causes connection and conductivity issues. While tarnishing might not always affect performance, it can have cosmetic implications. A tarnished connector may be perceived as unreliable or damaged, leading to concerns about its performance.

Electrical Conductivity

Gold is the third most electrically conductive element, following copper and silver, due to its electron configuration. Although copper and silver surpass gold in conductivity, gold plating on connectors is often preferred because of its durability and corrosion-resistant properties, making it more suitable for long-term use.

Applications of Gold-Plated Connectors

Gold-plated connectors are vital in high-stress environments, such as military and aerospace applications. These areas demand connectors that endure extreme conditions while maintaining superior electrical and mechanical performance.

In addition, gold-plated connectors are valuable in applications that require frequent mating cycles, such as testing and instrumentation. Gold's durability and longevity are ideal for connectors subjected to repeated use.

At SV Microwave, gold plating is applied to various RF connectors, including blind-mate connectors and those with center contacts. Any connector featuring a socket is also gold-plated, as its base, typically heat-treated Beryllium Copper, is prone to corrosion if unprotected.

Passivated Stainless Steel and Other Alternatives

While gold plating on connectors offers numerous advantages, several alternatives exist, including nickel, silver, and passivated stainless steel. These materials can offer cost-effective solutions while providing varying degrees of corrosion resistance.

|  |  |

Passivated Stainless Steel

Passivated stainless steel is commonly used for SV’s threaded connectors and offers an excellent alternative to gold plating. The passivation process involves treating steel with nitric or citric acid to remove free iron from the surface. This treatment eliminates impurities that cause rust and forms a protective oxide layer, making the stainless steel more corrosion-resistant. This process applies to our threaded connectors because of their stainless steel bodies.

Silver

Silver is more conductive than gold and can serve as an alternative in some applications. However, gold’s superior corrosion resistance often makes it the preferred choice.

Nickel

Nickel plating offers a more cost-effective solution than gold. While it provides a degree of corrosion resistance, it does not match gold’s long-term conductivity.

One way SV Microwave utilizes nickel is with nickel underplating beneath the gold plating. This prevents copper bleed-through, a process where the copper base material seeps through the gold layer, leading to corrosion over time.

Gold Plating: The Superior Choice for Critical Applications

While these alternatives provide certain advantages, none can match the reliability, durability, and corrosion resistance of gold plating on connectors, making it the best option for critical applications.

The Effects of Gold Thickness, Hardness, and Quality

The thickness and hardness of the gold layer on connectors can affect performance and durability. SV Microwave uses different gold thicknesses and hardness levels depending on the specific connector's needs.

Thick Plating

Thick gold plating, typically measured at 1.27 microns or above, provides superior corrosion resistance and is favored in applications that face environmental stressors or high mating cycles.

Thin Plating

Thin gold plating, around 0.25-0.76 microns, is sufficient for connectors used in low-stress environments. While it offers a cost-effective solution, thin plating can be porous, which may increase the chances of corrosion. As mentioned earlier, SV combats this with nickel underplating, adding an extra layer of protection.

Gold Hardness

Gold hardness, which varies based on purity levels, affects how well the gold performs under different conditions. With purity levels typically ranging from 99% to 99.9%, hard gold, gold containing more impurities, is particularly suited for connectors that must withstand sliding contact or high mating cycles, as its toughness helps prevent degradation over time.

Gold Embrittlement

Gold plating on connectors in any situation may cause gold embrittlement during the solder cycle, compromising performance. SV Microwave offers a line of Pre-Tinned Connectors designed to remove gold from solderable areas, preventing embrittlement. SV also provides degolding services for cable ferrules, tailored to specific applications. Reach out to our engineers today to learn how this can benefit your design: applications@svmicro.com.

Gold Plating, the Preferred Choice

Gold plating remains the preferred choice for connectors requiring superior durability, corrosion resistance, and consistent performance, especially in demanding environments. While alternatives, like passivated stainless steel, silver, and nickel, offer certain advantages, none provide the same level of long-term reliability that gold does. Whether designing for high-stress applications or seeking a cost-effective solution, understanding the role of plating materials is critical. At SV Microwave, we offer a range of gold-plated connectors and alternative solutions tailored to meet diverse industry requirements. Contact us today to find the best solution for your application at applications@svmicro.com.