The Role of Advanced Materials in RF Connector Innovation

Different connector materials directly impact different properties. Different bases, platings, and dielectrics all play key roles in determining how a connector performs and which application it’s best suited for. Learn more below!

Connector Base

The base material of an RF connector is the primary metal alloy forming its body and conductive structure.

Typical Base Material

The base of our connectors will often be heat-treated Beryllium Copper. Heat treating Beryllium copper first heats the alloy to high temperatures, dissolving the beryllium into the copper matrix and creating a soft and ductile solid solution. Then, the temperature drops to cause the precipitation of fine beryllium-rich particles within the copper matrix, increasing the alloy’s strength.

Beryllium copper is the ideal connector base for many of our connectors because it combines corrosion resistance, reliable signal transmission, high mechanical strength, elasticity, and durability, creating long-lasting connections.

Plating

Plating refers to the thin metallic coating applied over the connector’s base material, particularly on the contact surfaces and mating interfaces.

Common Materials

One of the most popular connector materials for plating is gold due to its durability and corrosion-resistant properties. Gold is one of the least reactive metals, as it does not react with oxygen or moisture. This makes it highly resistant to oxidation under environmental stressors and base metal bleed-through, providing consistent performance.

Passivated stainless steel is commonly used for SV’s threaded connectors and offers an excellent alternative to gold plating. The passivation process involves treating steel with nitric or citric acid to remove free iron from the surface. This treatment eliminates impurities that cause rust and forms a protective oxide layer, making the stainless steel more corrosion-resistant. This process applies to our threaded connectors because of their stainless steel bodies.

Nickel plating offers a more cost-effective solution than gold. While it provides a degree of corrosion resistance, it does not match gold’s long-term durability. One way SV Microwave utilizes nickel is with nickel underplating beneath the gold plating. This prevents copper bleed-through, a process in which the copper base material seeps through the gold layer, resulting in corrosion over time. While gold is able to prevent base metal bleed-through on its own, the nickel underplating helps secure its longevity.

Silver is more conductive than gold and can serve as an alternative plating material in some applications. It also provides the lowest insertion loss. However, gold’s superior corrosion resistance often makes it the preferred choice.

Specialized Materials

There are also more specialized forms of plating, such as black chrome. Ideal for military applications, black chrome ensures a completely non-reflective finish.

Another way plating can be used in a specialized way is the absence of a material. Since our non-magnetic connectors are made of Beryllium Copper with zero nickel plating, they have a low magnetic susceptibility (10^-5 max), no electric field distortion, and a magnetic field strength of less than .1 milligauss. Favoring a different plating material over nickel is part of what makes these connectors perform well in non-magnetic applications, like quantum computing.

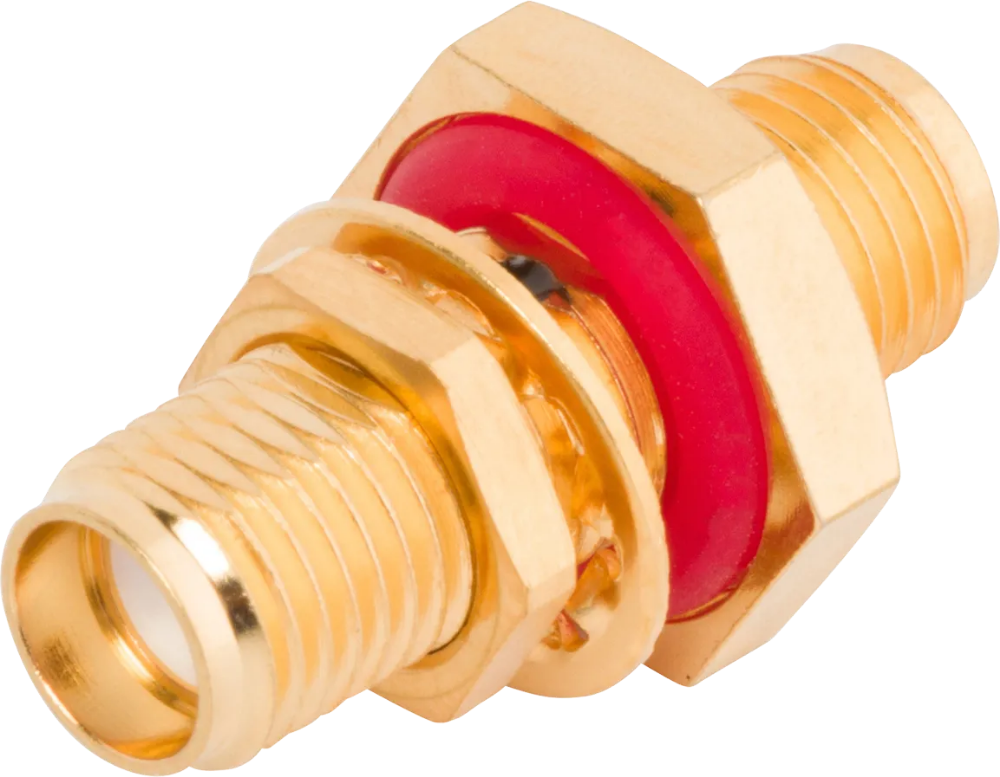

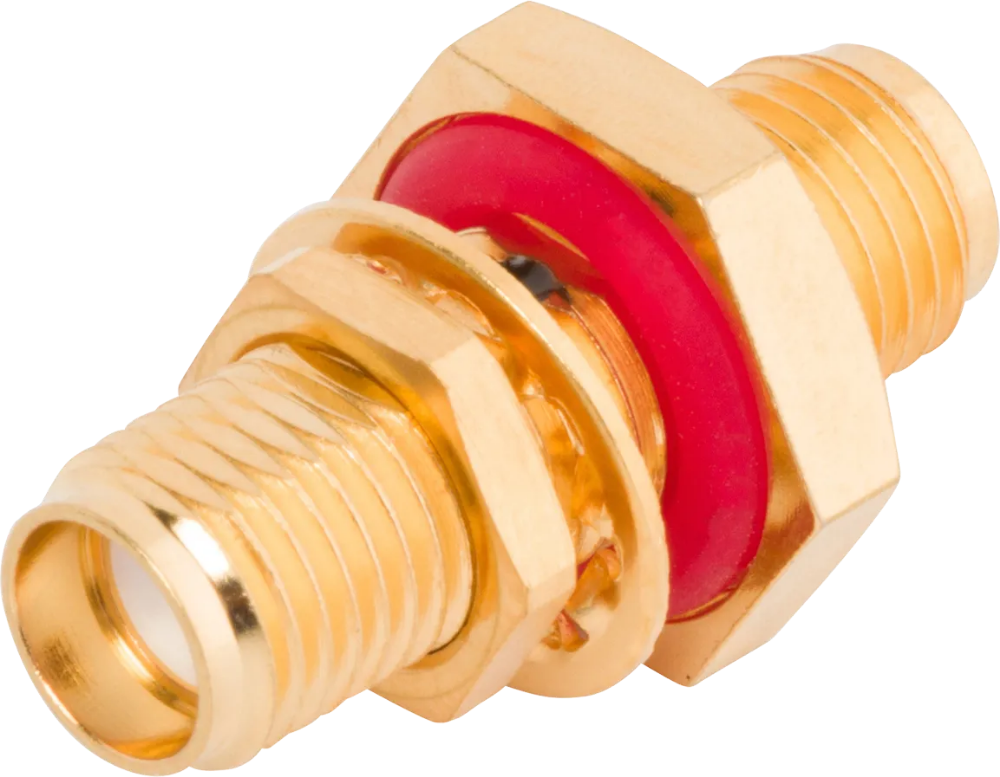

Non-Magnetic Bulkhead Connector

Skin Effect

In some cases, plating can be more important than the base material. This is due to the skin effect. As you go up in frequency, the way the signal moves changes. Instead of being distributed uniformly, it flows on the outside “skin” of the connector, making the plating what needs to be conductive.

Dielectrics

The dielectric in a connector is the insulating material that separates the center conductor (or signal path) from the outer conductor or body.

Reflow Stable

A common way SV advances a connector’s performance is by using a glass or epoxy seal as the dielectric material. This provides heat-temp stability and makes them reflow stable.

Using PTFE, the common dielectric for PCB connectors, often results in growth throughout the solder reflow cycle, as the PTFE material cannot withstand the high temperatures found in a solder oven. This can cause connectors to pop off the board and affect signal integrity - leading to the connector having to be replaced.

PCB Connector with PTFE tilting and lifting off board during solder reflow

Reflow Stable PCB Connector during reflow. The connector stays firmly on the board

The coefficient of thermal expansion (CTEs) of Kovar and Corning 7070 Glass are closely matched, unlike the more varied CTE of PTFE. Similar CTEs mean minimal damage during heating as both materials expand and contract at comparable rates.

Waterproofing

A connector material that can significantly impact the performance of connectors is the O-ring and its placement. SV utilizes these in our IP67/68-rated waterproof interconnects, as they feature a series of O-ring seals, both internal and external. The external O-ring on the bulkhead flange prevents leaks and contamination. The additional internal O-ring, strategically placed in the dielectric and center contact, ensures that water cannot ingress through the connector. This dual-layer protection makes them ideal for high-pressure, vacuum applications, as well as preventing liquid or gas leakage.

Power Handling

If a connector needs to handle more power, putting a heat sink on it will help. Often, connectors burn up because the temperature causes them to melt. Choosing more thermally conductive materials can help transfer heat away from the center conductor and to the body. This, in turn, allows you to push more power.

recent releases

The Role of Advanced Materials in RF Connector Innovation

Different connector materials directly impact different properties. Different bases, platings, and dielectrics all play key roles in determining how a connector performs and which application it’s best suited for. Learn more below!

Connector Base

The base material of an RF connector is the primary metal alloy forming its body and conductive structure.

Typical Base Material

The base of our connectors will often be heat-treated Beryllium Copper. Heat treating Beryllium copper first heats the alloy to high temperatures, dissolving the beryllium into the copper matrix and creating a soft and ductile solid solution. Then, the temperature drops to cause the precipitation of fine beryllium-rich particles within the copper matrix, increasing the alloy’s strength.

Beryllium copper is the ideal connector base for many of our connectors because it combines corrosion resistance, reliable signal transmission, high mechanical strength, elasticity, and durability, creating long-lasting connections.

Plating

Plating refers to the thin metallic coating applied over the connector’s base material, particularly on the contact surfaces and mating interfaces.

Common Materials

One of the most popular connector materials for plating is gold due to its durability and corrosion-resistant properties. Gold is one of the least reactive metals, as it does not react with oxygen or moisture. This makes it highly resistant to oxidation under environmental stressors and base metal bleed-through, providing consistent performance.

Passivated stainless steel is commonly used for SV’s threaded connectors and offers an excellent alternative to gold plating. The passivation process involves treating steel with nitric or citric acid to remove free iron from the surface. This treatment eliminates impurities that cause rust and forms a protective oxide layer, making the stainless steel more corrosion-resistant. This process applies to our threaded connectors because of their stainless steel bodies.

Nickel plating offers a more cost-effective solution than gold. While it provides a degree of corrosion resistance, it does not match gold’s long-term durability. One way SV Microwave utilizes nickel is with nickel underplating beneath the gold plating. This prevents copper bleed-through, a process in which the copper base material seeps through the gold layer, resulting in corrosion over time. While gold is able to prevent base metal bleed-through on its own, the nickel underplating helps secure its longevity.

Silver is more conductive than gold and can serve as an alternative plating material in some applications. It also provides the lowest insertion loss. However, gold’s superior corrosion resistance often makes it the preferred choice.

Specialized Materials

There are also more specialized forms of plating, such as black chrome. Ideal for military applications, black chrome ensures a completely non-reflective finish.

Another way plating can be used in a specialized way is the absence of a material. Since our non-magnetic connectors are made of Beryllium Copper with zero nickel plating, they have a low magnetic susceptibility (10^-5 max), no electric field distortion, and a magnetic field strength of less than .1 milligauss. Favoring a different plating material over nickel is part of what makes these connectors perform well in non-magnetic applications, like quantum computing.

Non-Magnetic Bulkhead Connector

Skin Effect

In some cases, plating can be more important than the base material. This is due to the skin effect. As you go up in frequency, the way the signal moves changes. Instead of being distributed uniformly, it flows on the outside “skin” of the connector, making the plating what needs to be conductive.

Dielectrics

The dielectric in a connector is the insulating material that separates the center conductor (or signal path) from the outer conductor or body.

Reflow Stable

A common way SV advances a connector’s performance is by using a glass or epoxy seal as the dielectric material. This provides heat-temp stability and makes them reflow stable.

Using PTFE, the common dielectric for PCB connectors, often results in growth throughout the solder reflow cycle, as the PTFE material cannot withstand the high temperatures found in a solder oven. This can cause connectors to pop off the board and affect signal integrity - leading to the connector having to be replaced.

PCB Connector with PTFE tilting and lifting off board during solder reflow

Reflow Stable PCB Connector during reflow. The connector stays firmly on the board

The coefficient of thermal expansion (CTEs) of Kovar and Corning 7070 Glass are closely matched, unlike the more varied CTE of PTFE. Similar CTEs mean minimal damage during heating as both materials expand and contract at comparable rates.

Waterproofing

A connector material that can significantly impact the performance of connectors is the O-ring and its placement. SV utilizes these in our IP67/68-rated waterproof interconnects, as they feature a series of O-ring seals, both internal and external. The external O-ring on the bulkhead flange prevents leaks and contamination. The additional internal O-ring, strategically placed in the dielectric and center contact, ensures that water cannot ingress through the connector. This dual-layer protection makes them ideal for high-pressure, vacuum applications, as well as preventing liquid or gas leakage.

Power Handling

If a connector needs to handle more power, putting a heat sink on it will help. Often, connectors burn up because the temperature causes them to melt. Choosing more thermally conductive materials can help transfer heat away from the center conductor and to the body. This, in turn, allows you to push more power.