Breaking Down the Anatomy of a Connector: Key Components and Their Functions

The anatomy of an RF connector is composed of 3 main parts: the center conductor, the insulator/dielectric, and the body. Each plays an important role in an effective connector. Learn more about these key components and their functions below:

Body

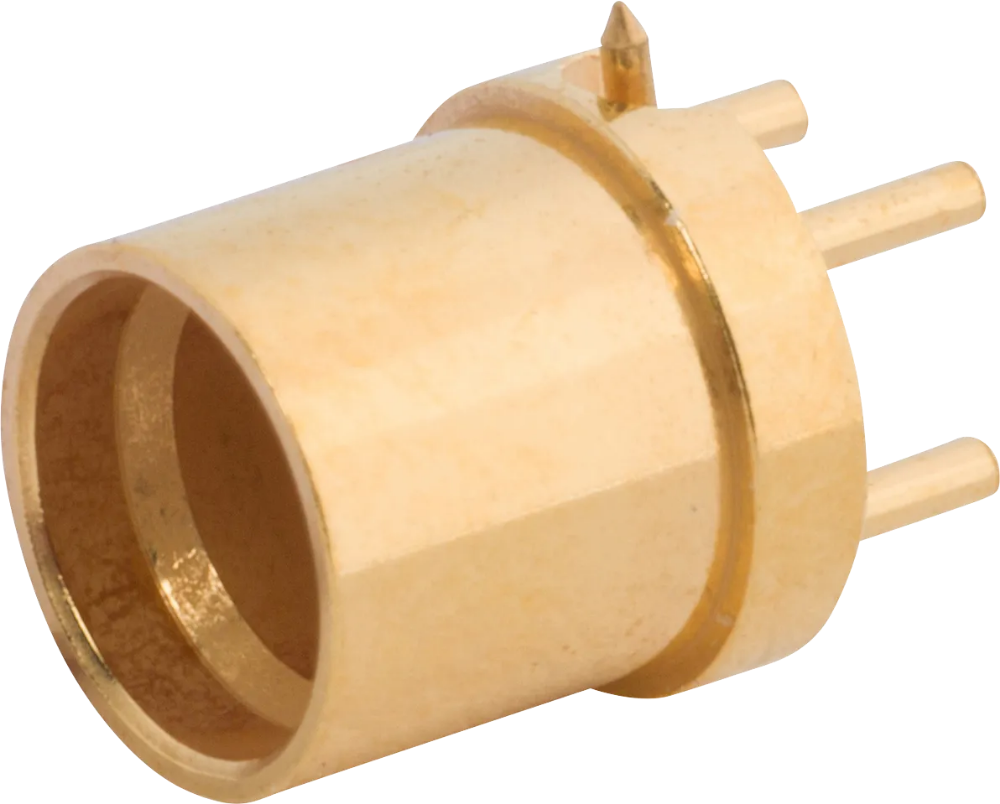

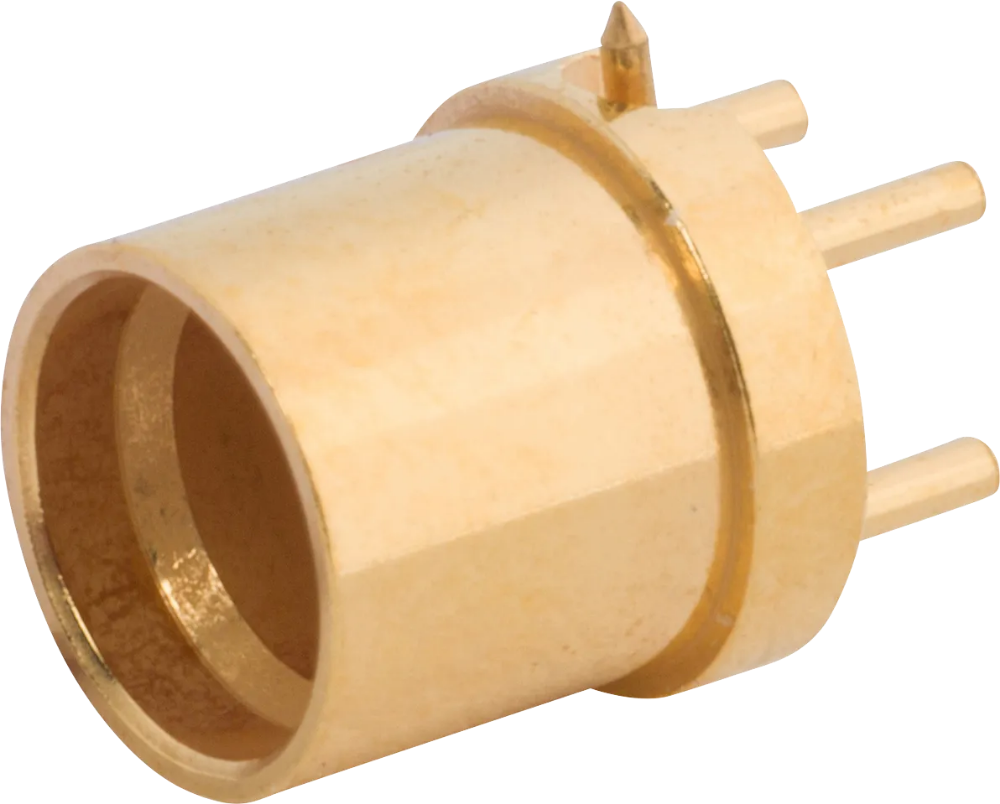

The body is the outer shell of the connector, and acts as the outer conductor and shield. This material is commonly made of berylium copper, gold, brass, or stainless steel. The body shields the signal from external interference, such as stress from harsh environments, and prevents the signal from leaking out.

The body also controls the mechanical connection to other connectors. With SV’s connectors, the coupling is often keyed, push-on, or threaded.

The body can also feature various components to interact with other equipment, such as thru-legs to provide a robust mechanical bond when soldered, or a flange on bulkhead connectors to offer increased mechanical stability and strength.

PCB Connector with Thru-Legs

Insulator/Dielectric

The insulator, or dielectric, is the insulating material, typically made of plastic or glass/epoxy. This component surrounds the center conductor in order to maintain the precise distance between the center conductor and the body. Necessary for mechanical support, this controls the connectors' impedance and is designed to minimize signal loss as much as possible.

SV uses a glass or epoxy seal as the dielectric in our Reflow Stable Connectors, specifically. Our glass seal connectors are rated up to 500° C, and our epoxy seal connectors are rated up to 255° C. These materials play a large part in these connectors retaining their internal geometries during solder reflow, maintaining electrical and mechanical performance.

.webp)

Glass Seal Dielectric in Reflow Stable Connector

Center Conductor

The center conductor works with the outer conductor to carry the RF signal. It’s also part of what controls the maximum frequency range. This depends on the size of the center conductor and the ID of the outer conductor.

The center conductor is often made of a conductive material like copper, but may be plated with gold for better contact and durability. Since gold is one of the least reactive metals, it’s highly resistant to oxidation under environmental stressors and often chosen for plating due to its corrosion-resistant properties.

Understanding the Anatomy of a Connector

Understanding the anatomy of the connector helps clarify how each component contributes to the overall performance. The body acts as the outer conductor and shield, so the signal is retained in the connector, the insulator maintains the precise distance between the center conductor and the body, and the center conductor works with the outer conductor to carry the RF signal.

recent releases

Breaking Down the Anatomy of a Connector: Key Components and Their Functions

The anatomy of an RF connector is composed of 3 main parts: the center conductor, the insulator/dielectric, and the body. Each plays an important role in an effective connector. Learn more about these key components and their functions below:

Body

The body is the outer shell of the connector, and acts as the outer conductor and shield. This material is commonly made of berylium copper, gold, brass, or stainless steel. The body shields the signal from external interference, such as stress from harsh environments, and prevents the signal from leaking out.

The body also controls the mechanical connection to other connectors. With SV’s connectors, the coupling is often keyed, push-on, or threaded.

The body can also feature various components to interact with other equipment, such as thru-legs to provide a robust mechanical bond when soldered, or a flange on bulkhead connectors to offer increased mechanical stability and strength.

PCB Connector with Thru-Legs

Insulator/Dielectric

The insulator, or dielectric, is the insulating material, typically made of plastic or glass/epoxy. This component surrounds the center conductor in order to maintain the precise distance between the center conductor and the body. Necessary for mechanical support, this controls the connectors' impedance and is designed to minimize signal loss as much as possible.

SV uses a glass or epoxy seal as the dielectric in our Reflow Stable Connectors, specifically. Our glass seal connectors are rated up to 500° C, and our epoxy seal connectors are rated up to 255° C. These materials play a large part in these connectors retaining their internal geometries during solder reflow, maintaining electrical and mechanical performance.

.webp)

Glass Seal Dielectric in Reflow Stable Connector

Center Conductor

The center conductor works with the outer conductor to carry the RF signal. It’s also part of what controls the maximum frequency range. This depends on the size of the center conductor and the ID of the outer conductor.

The center conductor is often made of a conductive material like copper, but may be plated with gold for better contact and durability. Since gold is one of the least reactive metals, it’s highly resistant to oxidation under environmental stressors and often chosen for plating due to its corrosion-resistant properties.

Understanding the Anatomy of a Connector

Understanding the anatomy of the connector helps clarify how each component contributes to the overall performance. The body acts as the outer conductor and shield, so the signal is retained in the connector, the insulator maintains the precise distance between the center conductor and the body, and the center conductor works with the outer conductor to carry the RF signal.